Weather Conditions Impacting Grain Quality

This year continues the chain of years with unusual harvest conditions driven by rapid weather changes in the latter part of the growing season. In mid-August, crops were significantly ahead of schedule in terms of maturity. Heat and moisture in May and June accelerated the pace of development, to the point that signs of maturity were evident by August 15, 2018. Rains followed by above-average temperatures began over Labor Day weekend, and have been repeated nearly every weekend to date. The forecast for the weekend of October 7 is more of the same – very heavy rains with intermittent warm, sunny and high humidity periods. The 2018 crop is now at a point where the wet conditions are affecting quality.

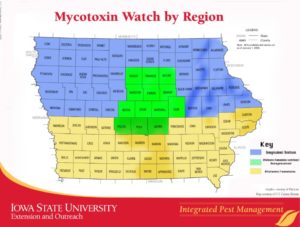

Corn moisture contents vary widely but field mold is showing up. Most field molds grow on corn after blacklayer; rapid drydown normally prevents significant further problems. Fields should be scouted for molds because some species have the potential to produce mycotoxins. Mycotoxins are natural chemicals that are produced by certain types of ear rot fungi. These toxins are nonliving compounds and can have detrimental effects on both humans and animals if they are present in food or feed. Those fields should be harvested as quickly as possible and dried rapidly without a long period of wet holding. Field molds normally do not grow in storage after drying but wet holding and slow drying can cause growth and toxin increases before the corn is dry. The lower temperature and air drying systems will have difficulty in the weather conditions predicted to continue for the next 10 days. Run bin dryers as warm as manufacturer recommendations allow, and try to fill bins in stages to reduce depth and increase drying rates in individual bins. Rotating fills may require documentation for crop insurance purposes, to identify grain traceable to specific fields.

Allowable concentration levels of mycotoxins in food and feed varies by toxin, as well as the intended use of the final corn products. The United States Food and Drug Administration (FDA) and Health Canada have set legally allowed limits for the mycotoxin aflatoxin, and cautionary levels for fumonisins and DON. If grain or end products contain mycotoxins above the concentration limits, then law may require the grain or products to be destroyed, as these can be harmful to those consuming the grain or products.

The longer the wet weather persists the more risk of mold and toxins that there will be. The moderately warm temperatures forecast for the next 10 days will accentuate mold growth. Moldy grain does not automatically contain mycotoxins; some species are not toxigenic, and not all toxigenic species always produce toxins. This is why end users (ethanol plants, feed mills, wet mills) will be screening composite samples of early harvest deliveries to determine if there are concerns. The often-present “polka dots” from Cladosporium are an example of field mold, that will grade damaged but that does not produce a toxin.

Harvesting

Stalk strength is low; there will be increasing amounts of downed or broken stalks. Harvest downed corn first regardless of moisture content because mold growth is accelerated, and drydown rates are reduced. Consider cleaning this corn if possible because the larger mass of material through the combine will create more airflow clogging fines and foreign material. It is always recommended to remove the center of bins before long term storage. That need will be greater this year.

General corn quality is average at best, as indicated by test weights. The kernel fill was not as complete as last year; dry corn test weights probably will be around 54-56 lb/bu. This still meets grade standards but expect a shorter storage life than last year. Because of reduced fill and kernel size, protein contents will probably be below the 7.5% long term average. The critical management actions this year will be rapid drying without long holding periods and cooling as quickly as possible to preserve future storage life. Always, actions right at harvest are the most crucial in determining future quality the following spring and summer. Both temperature and moisture content are important in grain preservation, but often temperature control is the most immediately important if drying capacity is limited.

Mycotoxin levels may vary among diseased ears, and corn that appears to only have mild ear rot could still have very high mycotoxin levels. One should always assume that diseased kernels contain mycotoxins. For an accurate assessment, send grain samples to a professional laboratory for analysis; the Iowa State University Veterinary Diagnostic Laboratory is able to test grain quality. Local laboratories and grain inspection services may test individual corn samples for mycotoxins; however, sample testing can be expensive. Check with your local extension personnel for a more complete list of grain testing facilities in your area. The cost and submission procedures will vary by provider.

Soybeans

Soybeans experience fewer in field mold problems than corn, because field moistures are normally low (<13%). However, if the soak-dry cycles continue with more heavy rain, expect pod splitting and eventually grey colored beans. Freeze-thaw cycles would further accentuate the splitting but currently there are no forecasts for frost in the near future. Do not try to store field molded soybeans; the oil will become rancid and continued deterioration is likely. The grey beans will grade damage in the market, but likely will get worse in storage. Aerate them for cooling, then market them as soon as possible.

The same needs for removing the center core of bins and dropping the temperature as rapidly as possible apply to soybeans as corn. Notice in the storage time table above that soybeans spoil at a rate equal to 2% points wetter corn. Soybeans are normally 13-14% or less in the field.

Soybeans are often stored in unaerated bins or buildings; this removes both the cooling and drying capability of aerated bins. Wet fields and warm temperatures may require special handling to be sure that beans in unaerated bins are cool and dry.

For more information, visit https://crops.extension.iastate.edu/

Authors

Charlie Hurburgh

Agricultural and Biosystems Engineering

Erin Bowers

Post-Doctoral Research Associate

Iowa Grain Quality Initiative